You need the right tool for the job (Swiss Army knife courtesy of Victorinox)

Productivity is one of the main prerogatives for Singapore’s service-based and export-driven economy.

Unfortunately, it is also one of the toughest challenges to surmount.

As I’ve blogged previously, addressing our productivity challenge entails understanding what it means. This involves studying how man, method, machine, material and other means are combined to generate wealth for the enterprise in the most effective and efficient manner. Through the careful analysis and diagnosis of problem areas, organisational productivity issues can be resolved.What can companies do to improve their productivity – be they in the service or manufacturing sector?

Consider using these four productivity tools to not only improve your value added per worker but to improve your overall business performance.

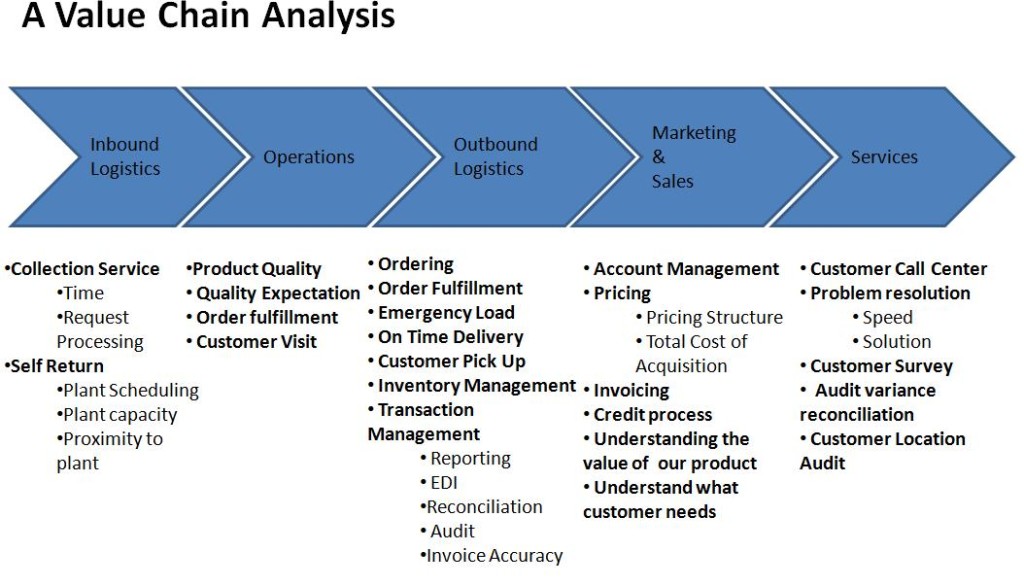

Value Chain Analysis

First, consider conducting a value chain analysis. Taken from Michael Porter’s classic – Competitive Advantage: Creating and Sustaining Superior Performance – it involves examining the various processes in a company which translates its inputs into outputs.

Each process is then articulated and measured to determine how efficient the company is, using available benchmarks from industry sources, historical records or government statistics.

An example of how this is done for a manufacturing company is visually represented by the diagram below:

Courtesy of Betty Feng’s Blog

Through value chain (or supply chain) analyses, companies can find ways to streamline processes and reduce the number of steps, time, effort or costs needed to complete a specific task in the chain. If necessary more drastic measures such as Business Process Reengineering (BPR) could be employed to speed things up by eliminating unnecessary hand-offs.

Using technologies available in Enterprise Resource Planning (ERP) or Customer Relationship Management (CRM) systems, information can be more readily shared between back-end functions and customer-facing departments. This improves the speed, accuracy and efficiency of transactions.

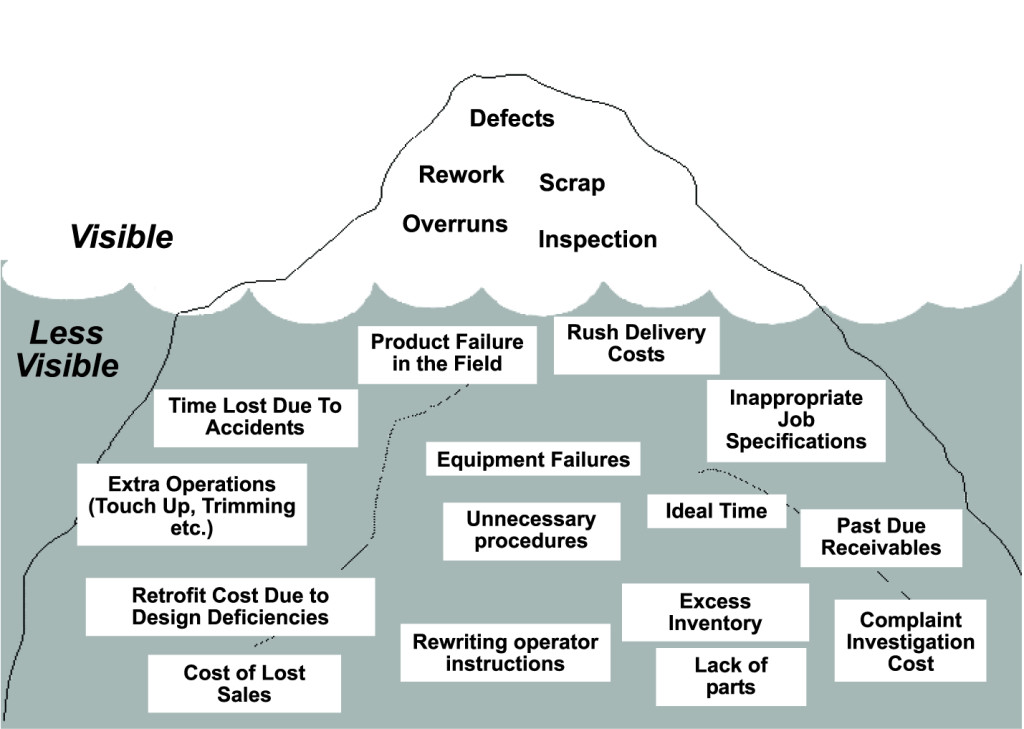

Cost Of Quality

Another way to determine where roadblocks may occur is to manage one’s Cost Of Quality. This is defined as the cost of NOT creating quality products or services, and can be classified as both visible costs and invisible costs as shown below:

Courtesy of Tap Root

The cost of quality can be divided into four categories of costs, namely:

1) External Failure Cost – Associated with product or service defects found by the customer, eg customer complaints, returned merchandise, warranty claims, recalls and even law suits.

2) Internal Failure Cost – Associated with defects that are discovered before delivery to the customer, eg rework, scrap, product faults, re-inspection, re-testing, downgrades.

3) Inspection (appraisal) Cost – Needed to determine the degree of conformance to quality requirements (measuring, evaluating or auditing), eg inspection, testing, audits, calibration, measuring equipment.

4) Prevention Cost – To reduce or eliminate poor quality by reducing the failure or inspection costs above. This is probably the best kind of cost to incur since it is often far lower than the above 3, and includes product reviews, quality planning, surveys of suppliers, work improvement teams, education and training.

The idea behind this is to reduce as many sources of cost as possible through preventive measures.

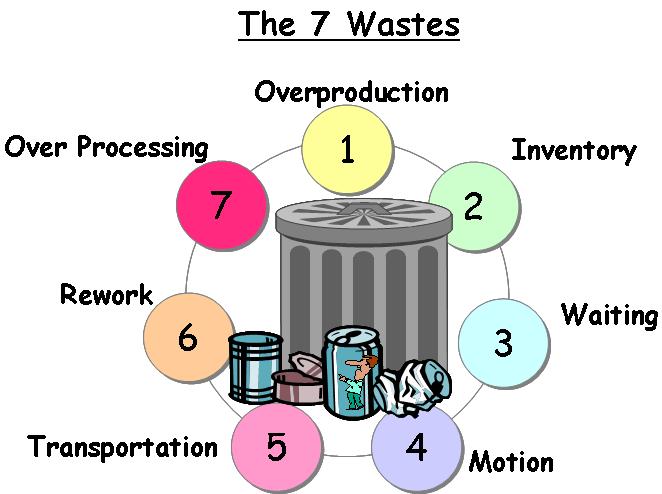

7 Wastes (or 7 W) and 5 S

Taken from Toyota’s lean methodologies, the 7 Wastes (or Muda in Japanese) can be represented by the acronym TIMWOOD, ie:

- Transportation – Increases risk of damage or loss, as well as unnecessary costs in time and resources;

- Inventory – Represents capital outlay that does not yield a direct value and may in fact incur lost opportunity cost;

- Motion – Wear and tear to products/equipment or injury to workers;

- Waiting – Time spent waiting is unproductive and wasteful;

- Over-processing – When too much engineering or features are needlessly introduced;

- Over-production – Excess material or products are being made; and

- Defects – Costs incurred in rework, rejects and rescheduling.

These different wastes can be represented by the diagram below:

Courtesy of Tony Wong’s Blog

Working hand in glove with the 7 Wastes are the 5 S which is also taken from Japanese concepts of lean manufacturing. These represent the Japanese words seiri, seiton, seiso, seiketsu, and shitsuke. Translated to English, they are to…

- Sort – Housekeep and prioritise to eliminate anything unnecessary – tools, parts, instructions, documents, and so forth. Everything needs to be either kept properly or trashed.

- Stabilise (or Straighten) – Ensure that stuff are properly categorised neatly, especially tools and information that needs to be frequently used.

- Shine (or Sweep) – Keep workplaces clean, tidy and organised at all times.

- Standardise – Where possible, adopt a similar modular approach to offices or counters or interfaces. Franchised outlets like McDonald’s are masters of systematisation.

- Sustain – Constantly maintain and review these standards of operation to ensure that they do not lag. If necessary, modernise them.

Again, this can be visually represented as follows:

Courtesy of TPF Europe BV

Net Promoter Score

Finally in consumer based retail and service businesses, productivity measures are often centred on people rather than processes. Here, being productive isn’t just a question of speed, reduced waste, or accuracy per se but the quality of customer experiences.

Often, a happy customer would patronize an outlet more frequently and recommend his or her family and friends to visit that outlet.

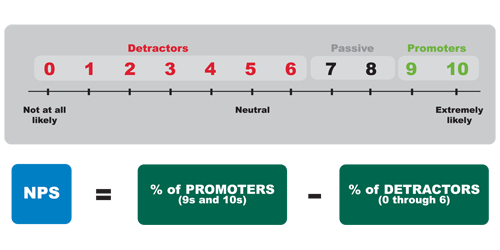

A good way to measure this is via the Net Promoter Score. Developed by Satmetrix, it is derived by asking customers how likely they would recommend [your company] to a friend or colleague.

Customers respond on a 0-to-10 point rating scale and are they are then categorised as follows:

- Promoters (score 9-10) are loyal enthusiasts who will keep buying and refer others, fueling growth.

- Passives (score 7-8) are satisfied but unenthusiastic customers who are vulnerable to competitive offerings.

- Detractors (score 0-6) are unhappy customers who can damage your brand and impede growth through negative word-of-mouth.

This is represented visually by the diagram below:

Courtesy of Satmetrix

Through managing and measuring their Net Promoter Scores, companies are able to determine how much positive word of mouth was generated by delighted customers. Businesses that generate a lot of goodwill through their product or service quality (like Starbucks) are usually able to reduce their marketing costs and improve their yield per customer.

Are there other tools to measure and manage productivity? Do feel free to share!

thanks for some cool easy to remember infographics for these 4 valuable concepts!

Some facts and other points given here are quite considerable and to the point as well, would be better to look for more of these kind for efficient results for your field of business.

Service Management Software

Always great to see the latest productivity application developments for small businesses. There are different types of productivity tools available in the market. It helps an organization in many ways like it reduces labor cost, increased revenue, accurate tracking of expense and time etc.

We have to choose the suitable application according to our company needs. Likewise, We are using cloud-based application and like to continue with Replicon Suite – http://www.replicon.com/olp/online-time-recording-software.aspx. we use it to to track time and bill customers for search marketing and advertising.